3D Printing Model Railroad Buildings: Marklin Villa Edition

The Marklin Villa has always been a “dream item” for Marklin collectors. For those that don’t know the legend of this wonderful piece, it’s worth first reading the wonderful article on Tischbahn (in the German language). As a quick summary, the Marklin Villa was never a full-production model or shown for sale in any catalog. Legend goes that it was made by Marklin employees for training in how to work with tinplate. But if you look at the incredible construction of these pieces, you might think otherwise.

The Villa is characteristic of other tin stations and buildings that Marklin made during the 1930s and even earlier. Everything is formed, stamped, shaped, and hand-soldered together. Edges that need reinforcing such as along the roof edges are “hemmed” wherein about 4mm of tin is folded over to double up the thickness and provide extra strength and makes the edge smooth.

The Villa has shown up several times in the past few decades on the auction block and also in the private market. It is believe that in addition to being featured on show layouts and displays, it was an item for export to England. It’s not surprising a few have shown up in England and the style of the Villa is rather characteristic of English architecture, but equally could be modeled after a German Villa too.

Can we reproduce the Marklin Villa?

Several noble hobbyists have made reproductions of the villa and done incredible work. Windows are cut and filed by hand and even after the parts are made, the soldering can take hours. The intricate details and geometric design of the roof is very difficult to model and recreate perfectly.

No doubt such a rare and sought after item deserves to be replicated and enjoyed by those who cannot afford to buy an original. And even for those that can afford it, one cannot simply just buy one any day of the week!

3D printing the Villa

After seeing the success of some modern 3D printers we thought it would be fun to try and tastefully recreate the model in plastic. Yes, it’s not made out of the original 0.35mm tinplate – but after all isn’t it the charming design and fine hand-painting that makes this item special and not the fact that it’s made out of metal? 3D printing offers a wonderful trade-off of quicker production time and also being able to accurately recreate the model over and over. Click here if you are interested to see other 3d models based off of Marklin toys.

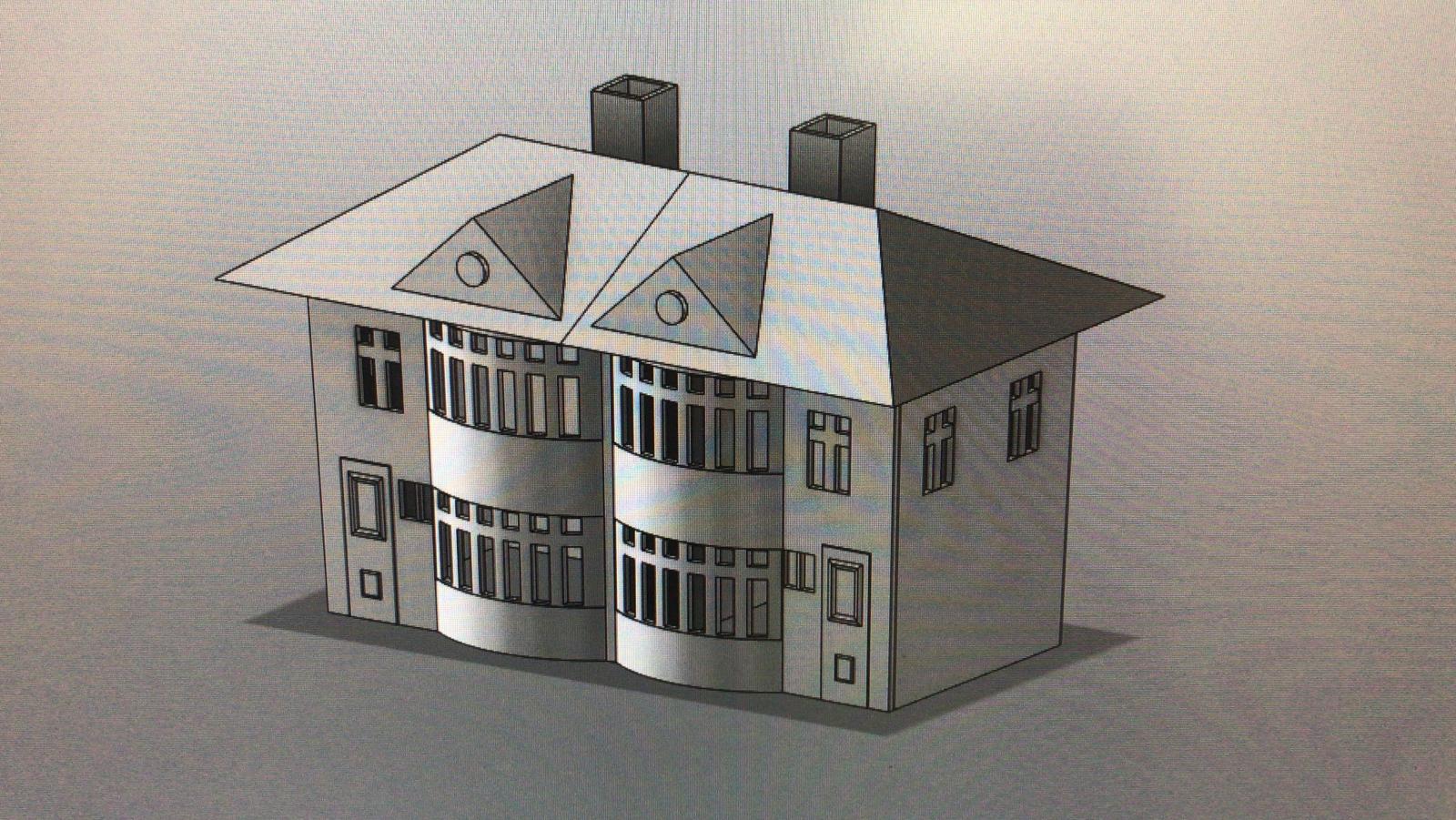

The first step when producing a new item is finding an accurate example to get measurements from and build a 3D CAD model. Luckily several photos online with known measurements helped immensely. A fellow collector in Germany with an original example also shared the exact dimensions of his model for mm accuracy in the final build. Because our reproduction is made out of plastic and could never be confused with metal, we are building to the exact specifications. If we were building it out of metal, we would likely add some “signatures” to the model so that it could never be passed off as an “original.”

Many many hours of CAD modeling later we have a fairly accurate 3D model of the Villa. Some detail parts like the chimney tops, roofs, and door overhangs are left off and will be added as metal detail parts later.

Find the 3D printer we used on eBay:

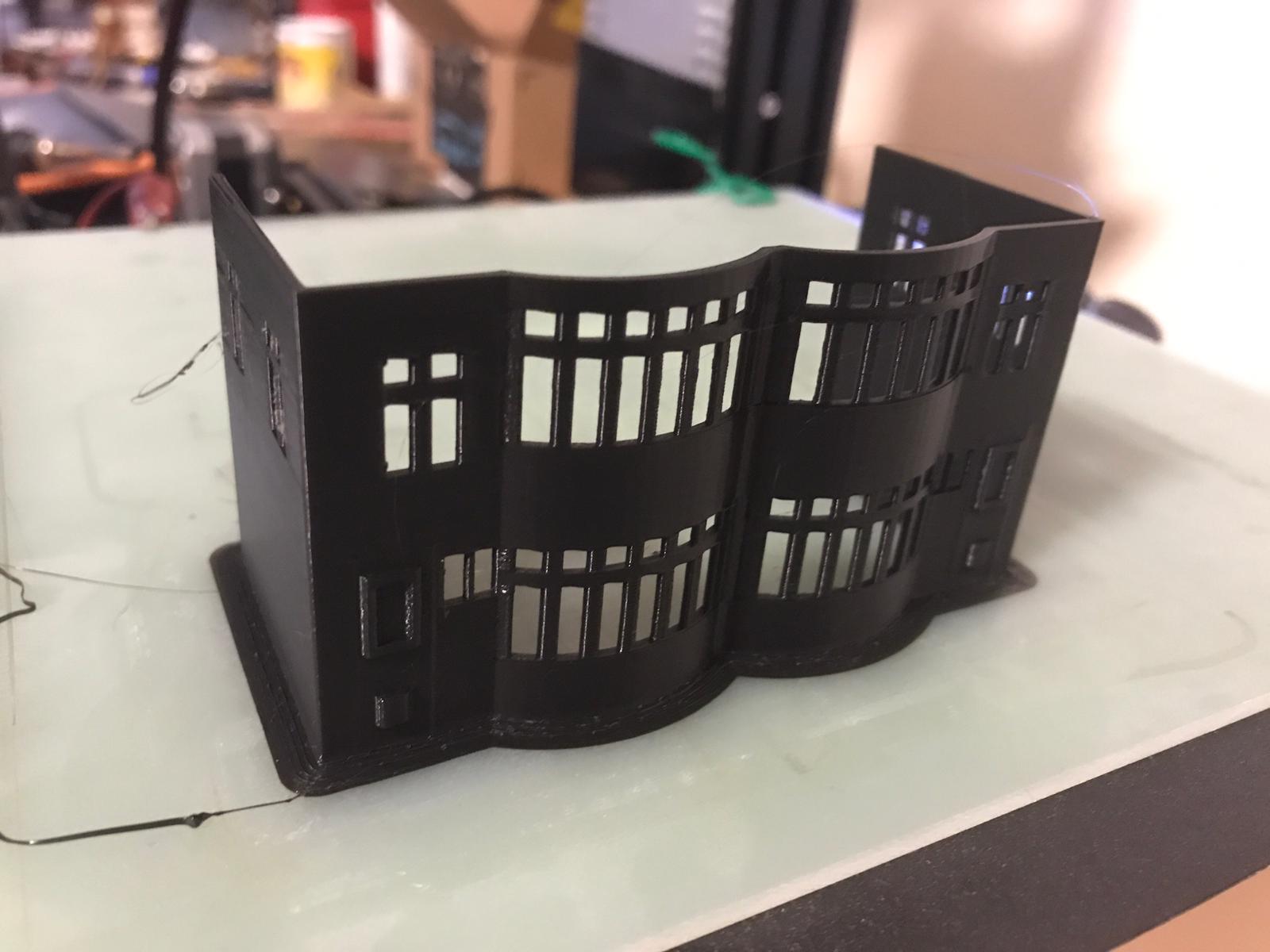

Next we separate the model into printable components. Naturally we will print the roof separately. The first print split each wall into a separate piece to be printed flat. This required adding “supports” to the model to account for the two front arched windows. This print design was later found to be not as optimal and the second print was done as all one piece and completely vertical with no supports! The fine .02mm resolution of the printing and careful adjustment of print settings allowed the print to turn out very well despite not having an support structure printed.

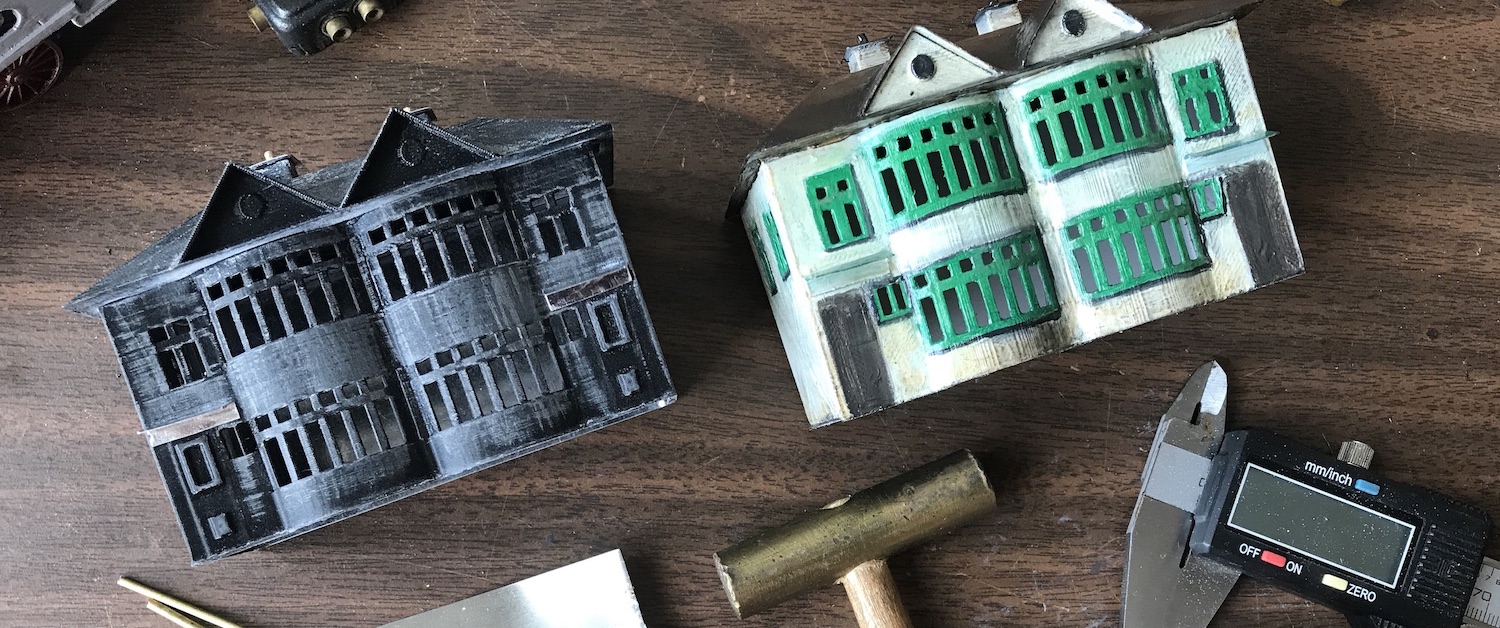

Construction and painting

While the initial printing setup, which included supports that had to be removed after printing, had many drawbacks in terms of print quality and post-processing time, the later vertical printing design was much faster and higher quality. In this version, the back wall is also not printed and instead a tinplate sheet was cut and bent to fit and glued to the plastic. This both added weight and some more realism with the metal.

The roof was also printed as a separate part and the chimney top detail pieces were also made to fit and glued. After full assembly, some weights were added to the inside of the roof to again give the feeling of metal instead of plastic. After full assembly, the building is primed with several coats of primer in order to cover the print lines as much as possible and build up a smooth layer of paint.

Painting was done with a mix of acrylic and oil paints. Acrylic paint provides fast drying times while oil provides superior blending and color mixing capabilities. In most cases the final coat of paint is always oil because it has a better overall finish that acrylic.

The last step is shellacing the entire piece with a thick coat in order to seal all the paint and provide a nice gloss coat. At this step as well some weathering and aging is done to give the appearance of almost 100 years of age.

Marklin Villa variations

Over the years we’ve identified several different variations of the villa – in both construction and painting. The one we have reproduced here is the “symmetric” version with two chimneys in the back. The more commonly seen version has one chimney on the side and one in the front in the center.

The version that we modeled this Villa after was symmetric, and had an interesting beige color seem and so we reproduced that painting schema as seen in the photo below. The model for this was sold once at a Christie’s toy auction.

So Finally Someone is useing 3D Printing to make Replicas of Marklin Items

Am Hopeing Someone will make a Replica of Der Adler 1935 Spur O

Great looking English semi-detached houses typical of 1930’s-50’s suburban London commuter belt and further.

I was also wondering can the 3d printers also print H0 figures and retain detail?

Hi Peter! Thanks for your comment – yes it is possible to print HO figures and still have fairly good detail. I will run some experiments soon and report the results.

Very happy to join the community of Märklin fans.

Since 1958 I have been a collector of OO and HO Märklin trains for the period 1935-1970.

I participated last year in 2020 in the Märklin metting at the Unimog museum in Gaggenau in Germany, very very beautiful.

I have a small collection that I complete each time I find a beautiful object (and according to my means!). I can send you some pictures.

I do a lot of bibliography, I worked a lot on “Villa Märklin” and I built it from an actual “villa”.

Sorry but my English is bad and very basic.

Thanks for your comment! I was at Gaggenau too! I remember seeing the VILLA displays and that inspired me to make some replicas too, out of 3D printing. I’ll send you an email – and your English is great!